Understanding Hot And Cold Corrosion In Marine Engines (Part II)

Tuesday, 12/04/2022, 16:17 GMT+7

Effect of Hot Corrosion

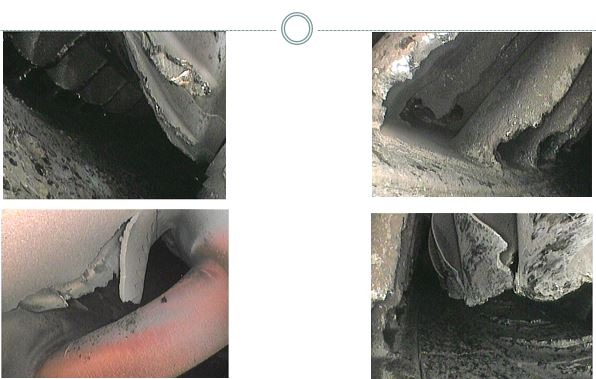

1. Erosion: It mainly takes place along the exhaust gas passages, as ash and carbon deposits from high-temperature exhaust gases wear metals. Because of this, the exhaust valve is profoundly affected.

2. Fused salt corrosion: At high temperature, Na and Va form corrosive fluxes, attacking and corroding exhaust valves, turbocharger nozzles and blades. The salts dissolve the protective oxide layers, facilitating further gas phase oxidation.

3. Gas phase oxidation: It is the effect of oxygen on metal engine surfaces in the hot exhaust.

How to control hot corrosion?

• Maintain exhaust temperature well below melting point of Na and Va complex (about 400c)

• Use of Sterlite coating or Nimonic steels on exhaust valve seat for protection from corrosion

• Use exhaust valve rotators to smoothen radial temperature distribution and to prevent repeated impact damage at a single point on the valve face

• Fuel additives like ash modifiers can be used which can modify and increase the melting point temperature of Na and Va complex formed when the ash is not in a molten form and not corrosive

• Controlling fouling of exhaust passages and machinery, i.e. regular cleaning and inspection of the exhaust manifold, frequent water washing of turbocharger, overhauling of the exhaust valve, etc.

Your Comments

Other news

For profit, companies are doing everything possible to cut fuel costs to the minimum using techniques such as slow steaming with low-grade fuels. However, the fuel oils that are used to run the ...

For profit, companies are doing everything possible to cut fuel costs to the minimum using techniques such as slow steaming with low-grade fuels. However, the fuel oils that are used to run the ...

For profit, companies are doing everything possible to cut fuel costs to the minimum using techniques such as slow steaming with low-grade fuels. However, the fuel oils that are used to run the ...

Analysis on the dual fuel engines of the liquefied natural gas (LNG) tankers Spirit of Hela and Gigira Laitebo proved the viability of using a single lubricant, Mobilgard™ M430 engine oil, to ...

__engine.jpg)

__Image_5-20-01.jpg)